Received in a bunch of boxes emblazoned with the S&S logo on the side, and there was a full compliment of goodies in there.

All said, this is some choice stuff. And whats better is that I didn't have to pay for it...

So, the first up is with the hardware which is gonna tie this whole thing together. It HAS to be 12 point head type. And that means that there is a good bit of fitting to be undertaken getting all the fasteners to have the correct grip lengths and whatnot.

Then there is the tappet blocks. They were scored and beat-up pretty bad. Some time with them in my loving hands and the bores were opened to the second oversize.

...and since this monster is going to have dedicated solid tappets, the passages in the blocks are tapped and then later will have a setscrew installed to block the oil flow. This will keep the oil volume dedicated to the parts of the engine which require it, and not needlessly blow flow into the tappets which no longer have hydraulic bodies needing to be pumped-up. Just keep the tap from breaking thru, that way the setscrew can bottom out, BINDING IT IN PLACE lessening the chance of ingestion. Ingestion is bad. (Remember that the tappets will get oiled during the piston upstroke when there is vacuum present in the gearcase, causing some oil to be drawn down the pushrod tubes and consequently oiling the tappets, rollers and camlobes..this ain't a knuckle, but oil still dribbles down them tubes....)

And since I was in a bore gauging mood, I took the time to make sure the right side bearing will lap out within a serviceable limit. Looks like I should be OK, just waiting on the left side bearings to arrive so I can begin line lapping....

Stroker Wheels..... Since I am kinda detail-oriented, I needed to see how good S&S wheels are out of the box. Busted out the Science Bench Center and a couple dial indicators and get to brass tacks. The drive side pinion is less than 0.00015" Total Indicated.

The right side pinion didn't move. Perfection!

But, the heads out-of-the-box were black wrinkled... Ugh! Black wrinkle looks good, but only when it is brand new, out-of-the-box! Once any dirt/ crap/ oil gets on it, it just goes downhill from there. So- I got to blast all that heavy-duty, tough-as-nails wrinkle off the castings, after I took the heads apart, of course...

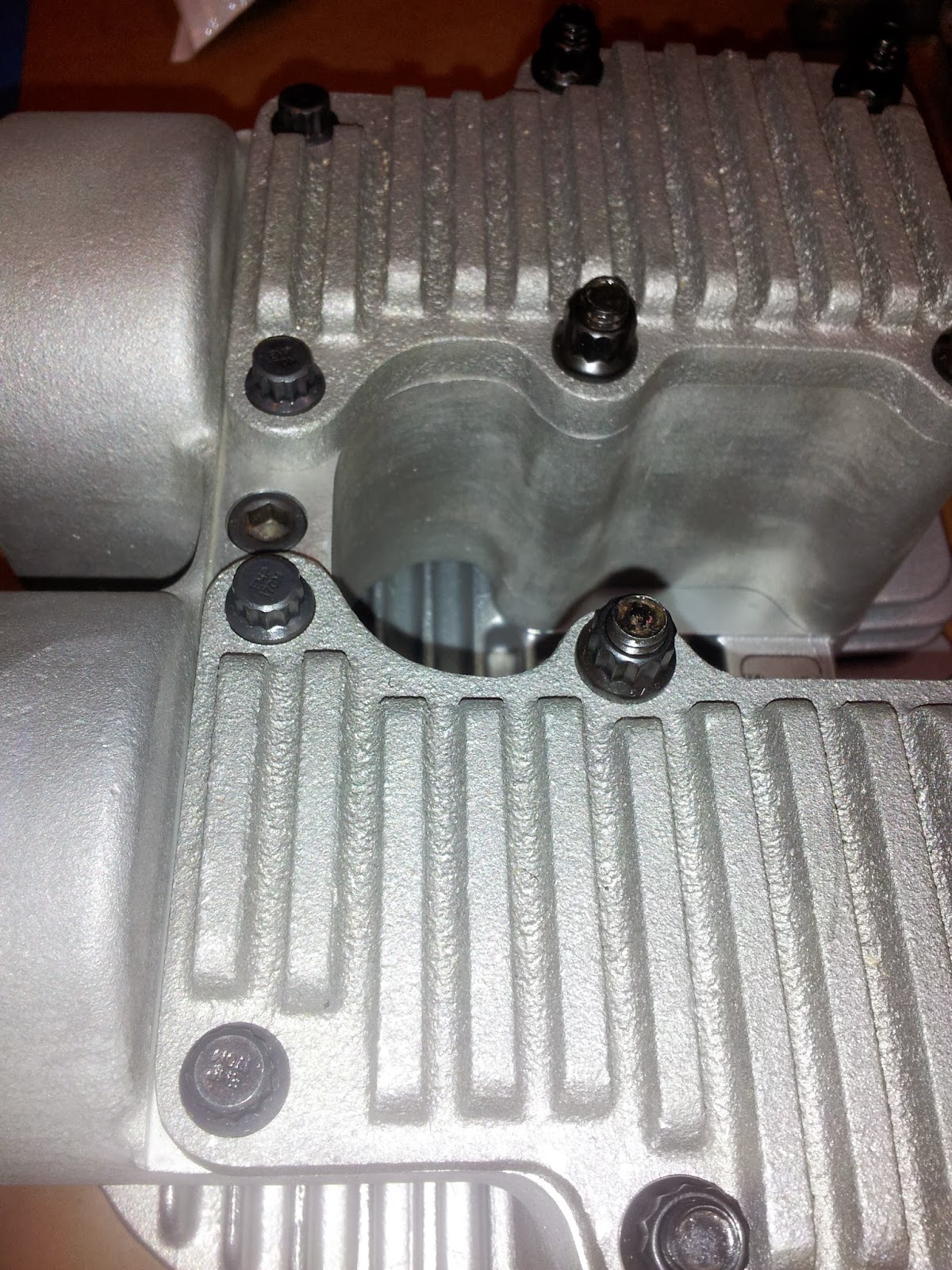

Then these totally BADASSED HotDock rocker boxes are going to be used. These are the only set to be on American soil, I believe. These things are over the top. Really.

A little hardware fitting, and viola, this is what they gonna look like....

The matter of oiling them is a small concern. I have an idea for a custom banjo style fitting.....remember that with this engine, cosmetic appeal is just as paramount to function. Everything has to be visually complimentary, and plumbing is an easy one to screw up. (So is wiring, for those of you taking notes...) But a well executed plumb job, minimal in fittings and aesthetic in layout, can look damn good.

Now, running two front heads has a few challenges on a shovel. First off, the matter of the cam. The cam requires the rear cylinder lobes to be swapped intake for exhaust since the valves are now swapped with a front head in the rear position... That's pretty easy to have done. Look for an installment relating to that in the future...

Then, with a front barrel in the rear position, the barrel requires to be notched for clearance to mimic the notch a rear barrel would have. Let the chips fly!

(Please pardon the 90 degree pics, my computer is not cooperating and it is already taking me way too long to do this post...)

Then there is beauty of the shovelhead having a symmetrical rockerbox mounting between front and rear heads. This means that the rear rockerbox will bolt up to the front head and vice-versa. Why this is important is the pushrod angle is different for each valve in any big twin (with the steepest angle being the front exhaust since it is the furthest outboard cam lobe). The rockerboxes and tappet blocks set these angles in the shovelhead, and therefore, if you can get the pushrod shrouds to fit into the boxes and blocks, the pushrod angles will be just fine.

So, really the only valve (on this engine) needing relief was the rear exhaust. A little trim to the cooling fins and clearance, Clarence

Mind you this now needs to have the fins blended and "cast" to make it look like these fins were always like this....That's more fashion than function....

And now the first motherfu^&*r. And I mean capital Motherf%^&er. Getting the rear exhaust to play nice with the front intake. Its miserable. Chips will have to fly. Ideas will will be borne and aborted.